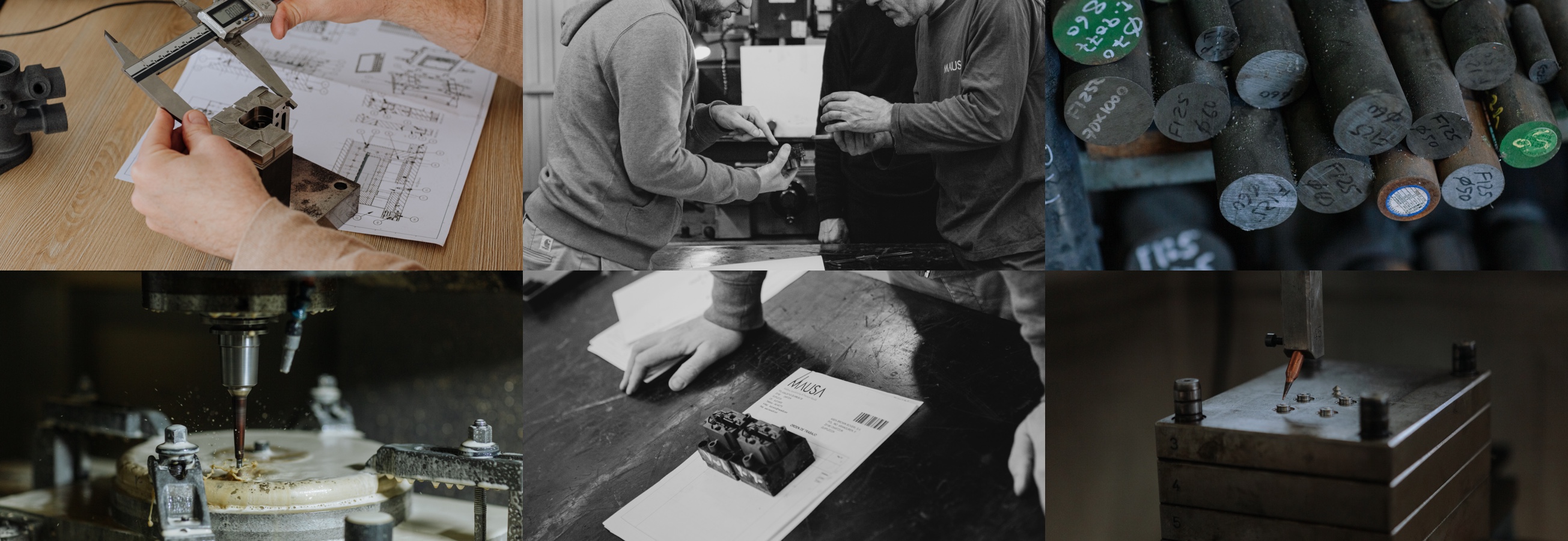

Moulds and Machining

We have 50 years of experience in manufacturing injection moulds for plastic and rubber-metal, as well as part machining. As an industrial tooling workshop, we offer comprehensive technical solutions, always committed to precision and quality. We have incorporated metal additive technology to increase the productivity and efficiency of our injection moulds, adapting to the most demanding standards of the industry.

SERVICES WE OFFER AS A TOOLING WORKSHOP

As a specialised tooling workshop, at Mausa we offer an integrated service that covers all stages of the process — from the technical design of the mould to its final manufacture, including repairs and maintenance. Our combination of experience, innovation, and precision allows us to work with the most demanding industry standards. In addition, we integrate advanced technologies such as 3D printing to optimise time, cost, and functionality in every project.

CONSULTING AND OPTIMISATION

We apply our know-how and experience to analyse the initial mould design and provide consulting on potential ways to improve it and guarantee project success.

WIRE EDM

We use wire EDM to cut up to 400 mm high, with precision and quality in all kinds of materials.

DESIGN AND DEVELOPMENT

At Mausa, we offer our design services: from definition to industrialisation and technical viability. With the most advanced software, we are able to define and design the best mould for the needs of each project.

QUALITY CONTROLS

Thanks to our rigorous quality controls throughout the process, we guarantee everything from mechanical and physical properties to final execution of the developed moulds and inserts.

MOULD PRODUCTION

We design and develop moulds for plastic injection, multi-cavity, two-material parts and other moulding processes such as rubber and rubber-metal, while always following the most stringent quality requirements.

MAINTENANCE AND REPAIRS

Our extensive know-how in designing and manufacturing moulds allows us to repair, modify and tune up other previously manufactured moulds.

3D COPYING AND MACHINING

We offer a comprehensive 3D copying and machining service, backed by an engineering team and the latest technology to respond to growing demand from the market with efficiency and precision.

TYPES OF MOULDS AND MATERIALS

Although rubber-metal injection moulds are the most common, at Mausa we also manufacture moulds for other applications and materials in our facilities.

Rubber-metal

- Injection moulds

- Compression moulds

- Transfer moulds

Plastic

- Injection moulds

- Hot chamber moulds

Aluminium-zama

- Injection moulds

MACHINING OF PARTS

At Mausa, we also offer machining services for industrial applications. We have a range of technologies that allow us to deliver the best possible service to our clients.

- Wire EDM

- Sinker EDM

- Milling

- Lathe with driven tools.

- Grinding.

TYPES OF MATERIALS FOR PART MACHINING

We provide machining services for all types of materials: ferrous, non-ferrous and plastics.

Ferrous materials

- Steels

- Stainless steel

- Special alloys

- Forged parts

- And others as required

Non-ferrous materials

- Aluminium

- Brass

- Copper

- Bronze

- Forged parts

- And others as required

Plastics

- Nylon

- Teflon

- Ertalon

- Bakelite

- Methacrylate

- And others as required

TECHNOLOGY

We work with modern machinery to make precision moulds following the highest quality and reliability standards required by each project.

| MAZAK VTC 760C | MAZAK VTC 300 | MAZAK VCN | CME FS0 | CMZ TC 30 |

|---|---|---|---|---|

| 1740 x 760 x 760 MM | 1700 x 760 x 760 mm | 1300 x 510 x 570 mm | 1200 x 650 x 650 mm | Turnable diameter 550 x 890 mm |

| 12000-RPM | 12000-RPM | 12000-RPM | 18000-RPM |

4000 RPM (eje-C + eje-Y) 12000-RPM |

| Hilo ONA OF35 | Hilo ONA AE 300 | Die-sinking QX6 |

|---|---|---|

| 600 x 400 x 400 mm | 400 x 300 x 250 mm | 1000 x 600 x 500 mm (die-sinking erosion ) |

| D3 CM cutter | Protch grinding machine | |

| 300 x 200 x 350 mm (specifically for tempered, very hard materials ) |

1200 x 550 x 500 mm |

Software

- CAD-CAM Siemens NX for design and machining.

- CAD-CAM Pro/ENGINEER for design and machining.

- CAM ESPRIT for wire cutting and lathe operations.

- CAD SolidWorks.

- Autodesk Moldflow

NEW MATSURA LUMEX:

3D METAL PRINTING WITH MACHINING

With the incorporation of a new hybrid metal printer with high-precision machining around 0.015 mm, we can produce inserts or dummy parts with internal conformal cooling channels, which are critical on parts with variable thicknesses or those that are difficult to fill. Thus, we can improve mould productivity up to 60%.

Metal laser sintering is a technique in which a laser is used to sinter or fuse metallic powder into the part being built. This hybrid technology combines sintering and machining, which are done in alternating fashion between the metal laser sintering and finishing machining every 0.01 mm, producing moulds with dimensional precision and surface softness at the same level as more precise machining centres. The LUMEX Avance-25 is also able to perform deep rib machining, an operation that conventional machining centres cannot; they instead turn to die-sinking EDM and subsequent polishing. Deep rib machining considerably shortens timelines and errors arising in the processes

ADVANTAGES OF MACHINING FOR HIGH-PRECISION MOULDS

Machining moulds with advanced technology significantly improves productivity, quality, and the durability of each part, optimising both the design and performance at every stage of the process.

> More efficient moulds :

with an increased injection productivity of about 50%

> Greater freedom in mould design :

60% reduction in working time from design to machining

> More precise parts :

Reducing dimensional errors to a minimum

> Sintering of porous areas :

To avoid accumulating gases and flow defects in parts

> Cooling channels optimised :

To keep the temperature controlled at all times .

> Printed part hardness of 36 HRC ,

with the option to harden to 52HRC

> We offer a hardening guarantee

of 1.5 million cycles .

DESIGN OF INJECTION MOULDS

Our technical team is responsible for the complete design of injection moulds, adapting to the functional, technical, and production needs of each client. We use advanced engineering software to define cavities, cooling systems, and ejectors, ensuring optimal mould performance from the very first cycle. We design with durability, efficiency, and ease of maintenance in mind.

REPAIR AND MAINTENANCE OF MOULDS

We offer a specialised service for mould repair, geometry modifications, and preventive maintenance to extend the useful life of your tools. Thanks to our experience in industrial tooling and our extensive machinery park, we guarantee precise and fast interventions. From minor adjustments to complete reconstructions, our goal is to minimise downtime and maximise productivity.

OUR MOULD WORKSHOP: CAPACITY AND TECHNOLOGY

In our mould workshop, we integrate state-of-the-art machining technology with an expert team in manufacturing and assembly. We have CNC centres, wire cutting, EDM, and metal additive manufacturing to cover all stages of the process. Our infrastructure allows us to handle everything from simple moulds to complex projects in short or long production runs.

Find the solution that best adapts to you with real case studies. You’ll learn the keys of the project, how Mausa helped the customer, the main characteristics of the project and the final result. We look forward to helping you.