SECTORS

Over the years, we have learned the specific characteristics of the various sectors our clients belong to. Through collaboration with them, we have continued to learn and grow, adapting our services and technology to consistently deliver the highest level of service.

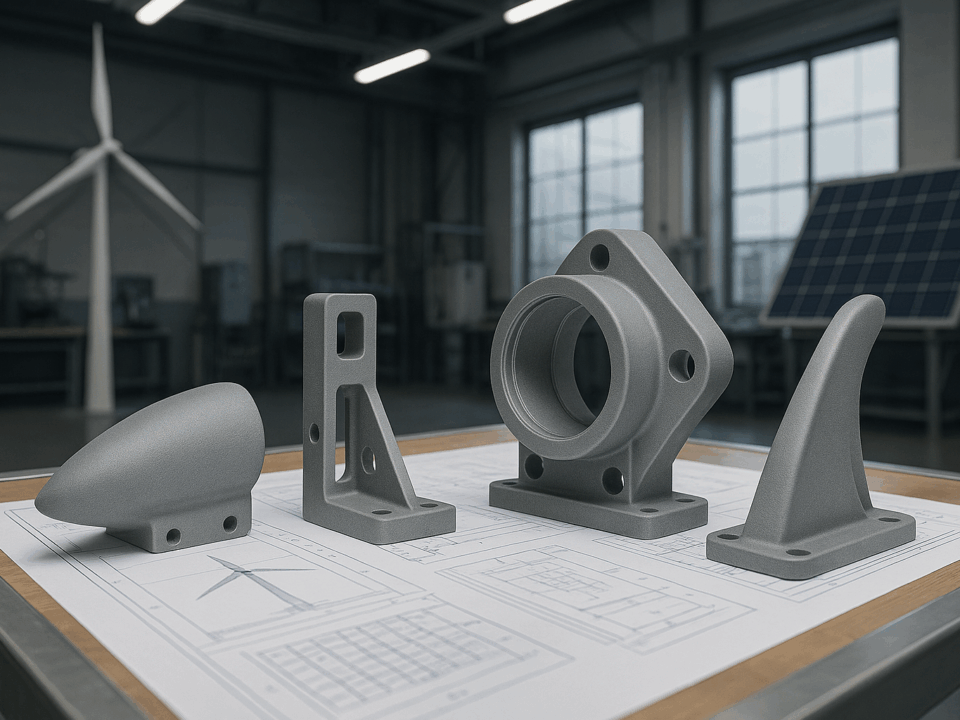

Industrial

At Mausa, we have been working for the industrial sector for 40 years. This experience includes die stamping, consulting, designing and producing moulds, machining parts and growing together with our customers. Now, thanks to our additive manufacturing service, we are able to offer solutions to all industrial needs and help your business grow exponentially. Thanks to the 3D printing revolution, we are able to offer new materials and designs, save on tooling, improve mould efficiency and shorten execution times – in short, cost savings that would have been unimaginable just a few years ago.

Case studies

Automotive

The auto industry is one of the sectors that has made the most of the advantages of additive manufacturing, as it allows large auto companies to cut costs, time and weight when producing complex parts. From quick and effective prototypes and models to small series manufacturing, as well as tooling solutions, 3D printing offers unlimited solutions that perfectly adapt to the needs of the auto industry. Thanks to our technology as well as our experience in the sector, Mausa offers fully customised components meeting the rigorous quality and warranty requirements of the automotive sector.

Case studies

Renewable energy

The potential for 3D printing in the energy industry is becoming more and more clear. This is just the beginning of the 3D printing revolution, as its possibilities for the energy industry and the environment are on the rise. Its advantages compared to traditional manufacturing include the capability to produce components with complex shapes and a weight reduction of up to 50%, consume fewer raw materials, produce less waste, reduce energy consumption and decrease time to market. At Mausa, we are trailblazers who are firmly committed to evolving with the industry to provide the best solutions for the sector’s specific needs.

Case studies

Robotics

The rise of robotics is unstoppable. In this sector, additive manufacturing has become its greatest ally. Thanks to this technology, it is possible to design and produce complex components quickly, precisely and in a customised way, reducing both manufacturing times and the costs associated with traditional methods. At MAUSA, we understand that in the robotics industry, the ability to rapidly iterate prototypes and create lightweight yet durable parts makes all the difference in innovation. That is why, through our high-quality and reliable MJF 3D printing technology, we help you create everything from optimised structures to specific tools for each application, enabling you to explore new solutions that were once unthinkable. For this reason, several leading companies already rely on us for the prototyping, production and customisation of their robots.

Case studies

Railway

In the transition towards a more sustainable world, railway transport is undoubtedly one of the strongest commitments at both the European and global level. The new generation of trains, whether for passenger or freight transport, requires new ways of designing, producing and maintaining their fleets. Thanks to our extensive additive manufacturing capability, we can produce parts on demand quickly, while reducing spare parts storage costs — a critical aspect for this sector. We also know that reliability and safety are essential in this industry, which is why we offer the possibility of manufacturing lightweight, strong and fully customised components.

Case studies

Medical

The medical industry is constantly changing, meaning innovation is key. Additive manufacturing offers absolute freedom to create unique solutions with a wide variety of finishes, characteristics causing 3D technology to gain more and more importance within the medical industry. One of the areas we know the most about is applications like orthopaedics, prothesis, inserts and medical tools, as we have light, wear-resistant materials and a wide range of customisable finishes. We can also assist you throughout the process, from design, development and prototyping to planning and custom series production.

Case studies

Packaging

Additive manufacturing has also revolutionised the packaging sector by enabling unique, creative and highly customisable designs. What used to be large-scale series that limited originality and differentiation can now be produced in small runs or prototypes with high-quality finishes, thanks to the additive manufacturing technology at our MAUSA facilities. This allows brands to position themselves in the market through innovative packaging that combines functionality and aesthetics, while reducing development and launch times. Our 3D printing technology thus becomes a strategic tool to turn ideas into attractive, efficient and competitive packaging solutions.

Case studies

Art and Luxury

What distinguishes the art and luxury sector is exclusivity. And what additive manufacturing allows is the creation of unique, fully personalised pieces — even single units. At Mausa, we work with artists and major brands to assist them with their custom creations or to develop distinctive identity elements that would be extremely difficult to achieve without our cutting-edge, high-precision additive manufacturing technology. All this enables us to meet their highest demands and become a true partner throughout almost the entire creative process, providing technical advice to achieve the best possible result for each artistic idea.

Case studies